What is it?

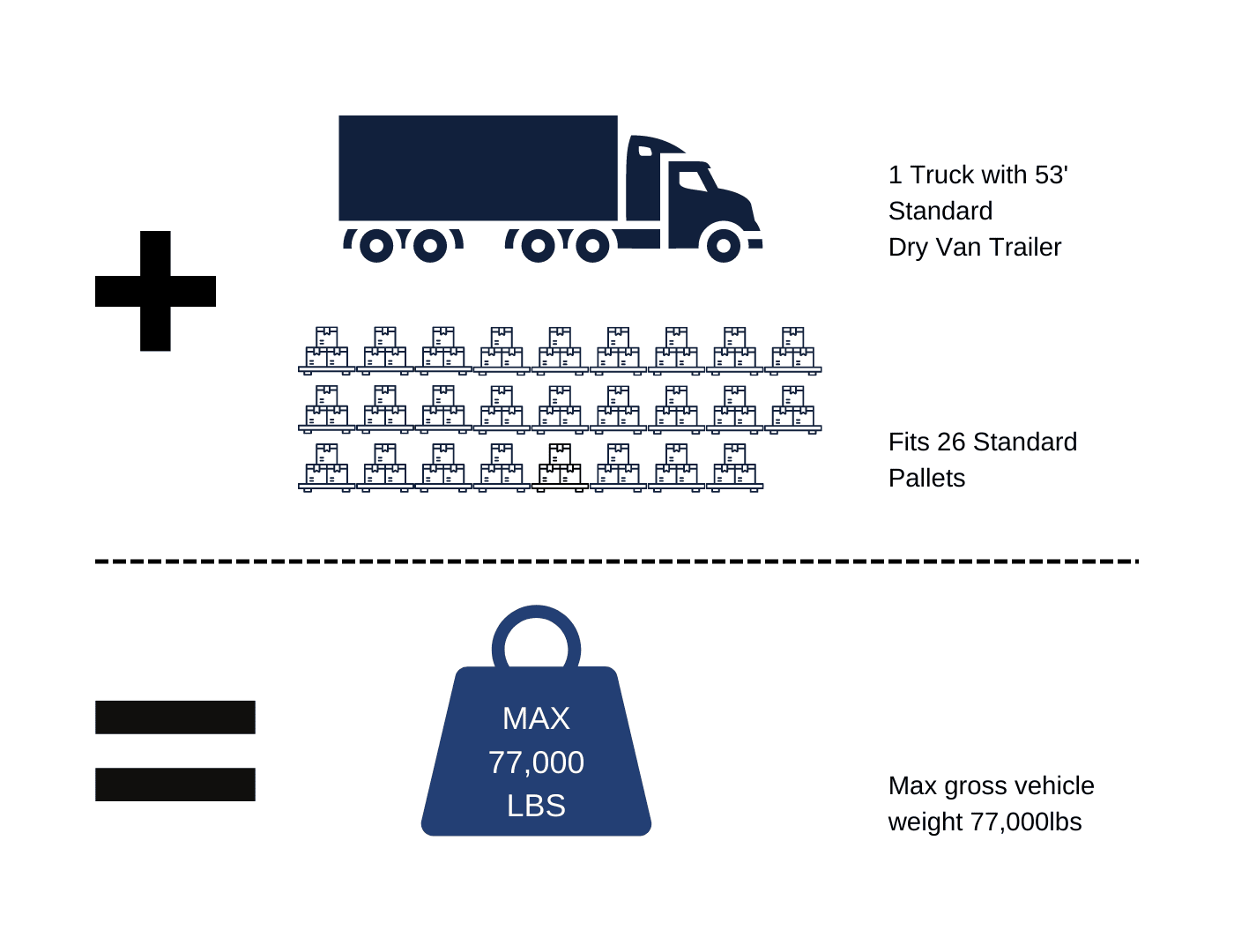

Full Truckload (hereafter FTL) is the largest service segment of trucking and receives its namesake simply because shippers either use all the available space in the truck's trailer or hire the truck at dedicated capacity. Trailers can vary in size but are most commonly 53- foot tandem axles with the ability to haul 43,500 LBS. Heavier freight is managed with Tri-axle 53-foot dry vans which can haul 52,000 - 77,000LBS depending on the state or province they operate. Other FTL equipment such as flatbeds will be covered in coming segments, but our focus for this segment will be on dry van or refrigerated trailers since they are the most common trailers used for FTL.

When is it used?

The majority of FTL services bring goods from one origin to one destination, but FTL can also be utilized in a dedicated process with multiple stops. For example, a driver could have two pick-ups in one state and deliver to one facility, but generally all in service of the same customer. The most common FTL shippers are those who require time-sensitive delivery or those who have higher customer volumes and consistent freight output. FTL carriers will bring freight of all kinds (FAK) from warehouses and distribution centers to retailers, food companies, manufacturing, and more. Put simply, the variety of goods utilizing FTL goes just like the old saying "if you bought it, a truck brought it".

Things to consider: Weight & Size

In general, shippers use an FTL carrier if they move freight ranging from 20,000 LBS to 77,000 LBS of freight, but State and Provincial laws can vary. Shippers or their transportation partners need to understand these regulations when shipping their products and goods. Depending on the state and route, shipments over those weight limits require special permitting, this is called Heavy Haul. For this reason, shippers need to how much their freight weighs in order to effectively and legally ship it.

Product or pallet size can also change a shipper's strategy. Standard truck trailers can fit up to 26 industry-standard pallets on the trailer's floor, plus more could be stacked on top. However, stacking can be tricky, and the shipper is required to ensure shipments are loaded safely to avoid shifting and damage.

To maximize space even more, FTL carriers can offer the option between standard dry van trailers described previously, or 'plated' dry van trailers. Shippers with wide cargo utilize a plated trailer since these trailers are 102 inches wide inside. One of the largest industries that use plated trailers is the Ready to Drink (RTD) industry. Companies like Coca-Cola or Pepsi need this type of equipment as their pallets are larger than standard and will not load effectively into a standard dry van without reducing the number of pallets able to be shipped in one truckload.

Another strategy for maximizing space is to utilize an LCV or long combination vehicle. These are common in Canada between major metropolitan distribution centres (like Montreal and Toronto), but less common in general since they have many special restrictions. Companies need special training, staff members, and locations to run them since they can only be used on certain highways. Additionally, the maximum gross weight does not change and is divided between the two trailers (with the second trailer also needing to weigh 10% less than the first), so it works best with lighter, bulky freight.