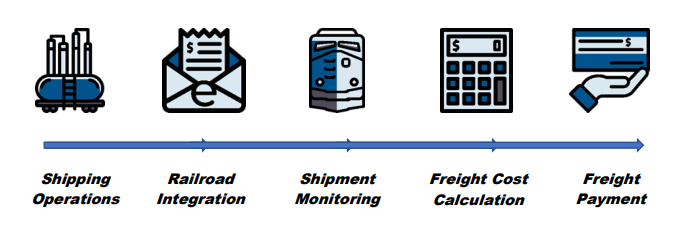

To manage the complete scope of rail fleet and shipping operations, seasoned logistics managers rely on robust systems to address all facets of rail fleet fulfillment processes for customer and production requirements. Such systems must address the entire end-to-end process encompassing and automating disciplines for shipping operations, railroad integration, shipment monitoring, freight cost calculation, freight payment, fleet maintenance, and analytics.

Key Logistics Requirements

Key requirements of an all-inclusive rail logistics system must provide:

- Robust functional integration with corporate ERP systems such as Oracle, SAP, JDE, and others.

- Automated and timely reporting and communication of key events among all participants.

- Operational and quality control of facility receiving, loading, unloading, and shipping processes.

- Robust AEI technology for field control of facility operations using stationary and portable scans.

- Electronic railroad communication for railcar orders, release, and shipment billing.

- Loaded and empty shipment monitoring to identify and expedite jeopardized shipments.

- Accurate freight cost calculation and automated railroad carrier payment.

- Robust fleet management tools for lease, maintenance/repair, and industry compliance.

- Business intelligence visualization to identify outliers, trends, and potential cost savings.

Such an advanced system allows fleet managers to implement industry best practices for control and automation of operations, freight reconciliation, and payment. When reviewing internal requirements, it is important to identify these capabilities which promote a fully integrated logistics process.