As cars are loaded and billing is given to the carriers, the shipper must provide a loaded weight so that the railroad can determine if it can move safely. Sometimes this is done by the railroad weighing the car and advising the shipper of the loaded weight, but more often today it is done by what is called a Weight Agreement. A Weight Agreement is when shipper and carrier agree to use the shippers' weights for the move without weighing the car prior to movement.

As the railroads close more and more scales across their systems, the ability to have a car weighed prior to billing is almost impossible. In most instances, the only time a car is weighed is when it is being blocked in a hump yard. The first time this can happen, in many moves, is several hundred miles after the origin point. If the car is then found to be overweight, the shipper will have to make arrangements to have some of the load transferred to another car before it will be allowed to continue forward. This can be a very expensive problem for shippers to deal with, which makes the weight information important. Other reasons why the weight information is important are for Regulatory Compliance as well as claim resolution.

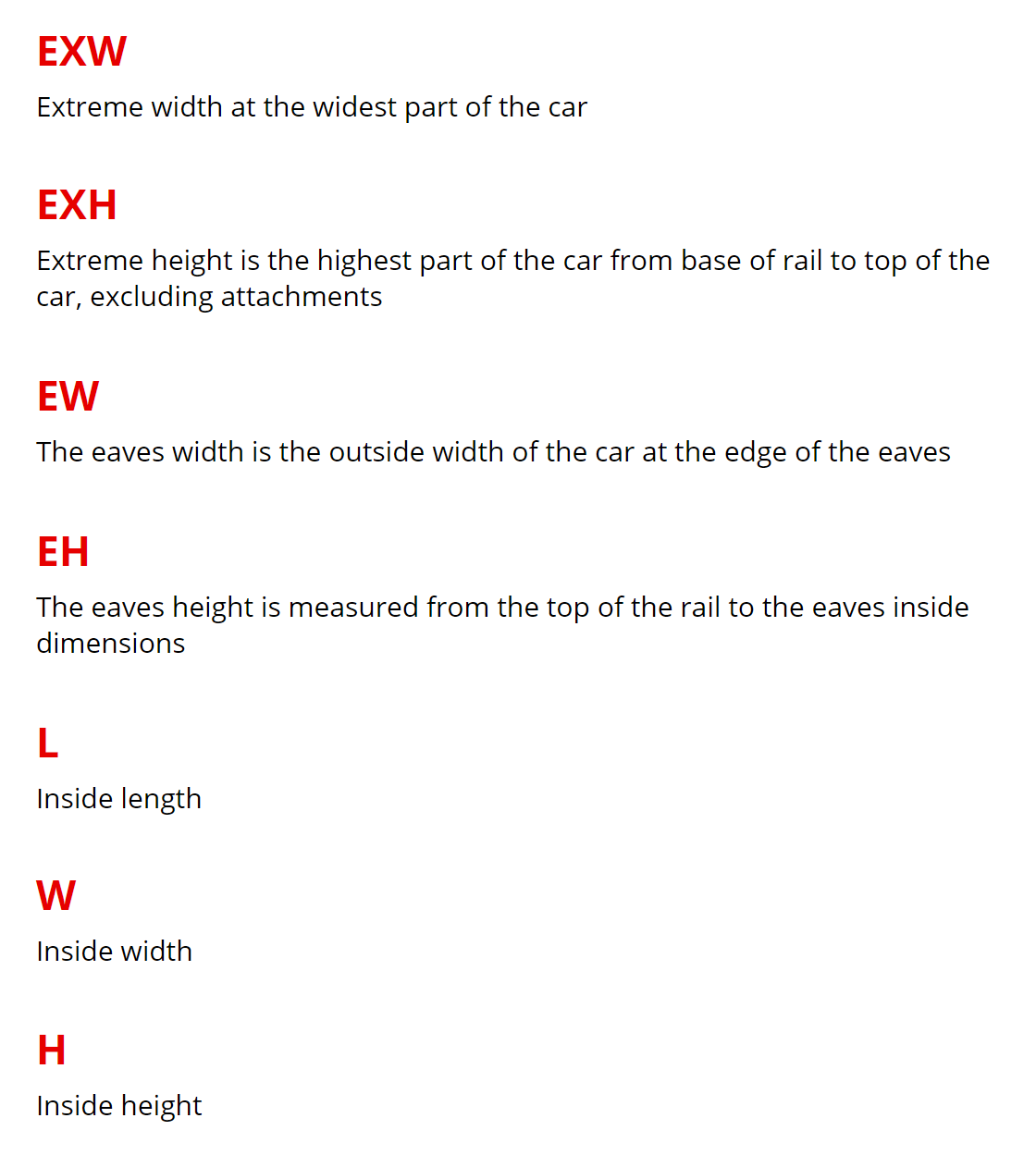

The dimension information that is stenciled on the cars gives the extreme heights, widths, inside lengths, and inside height. The following is a description of what each of the dimension marks mean: