Having too many railcars within a fleet can be costly and burdensome. Having too few cars can mean lost opportunities. While every situation is unique and there are more sophisticated calculation methods, the following is a model that allows for a simple way to determine how many railcars you need in your fleet.

Inputs:

- Average number of daily loads: How many cars are needed daily based on forecasted or historical volumes.

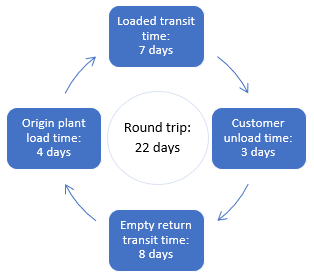

- Loaded transit time: The number of days from the origin loading point to the customer’s unloading facility.

-

- Measured from when the car is released from the origin facility to when the car is either constructively placed or actually placed at the customer.

- Customer unload time: The time that it takes the customer to unload the railcar.

-

- Measured from when the railcar is constructively or actually placed, to when the customer releases the cars.

- Empty return transit time: The number of days the car takes to return back to the origin facility.

-

- Measured from when the car is empty released to when the car is either constructively placed or actually placed with the customer.

- Origin plant load time: How many days it takes for the plant to load the car.

-

- Measured from when the car is constructively or actually placed, to when a new bill of lading and loaded release is reported.

Example:

Assume the customer loads on average 2 cars per day